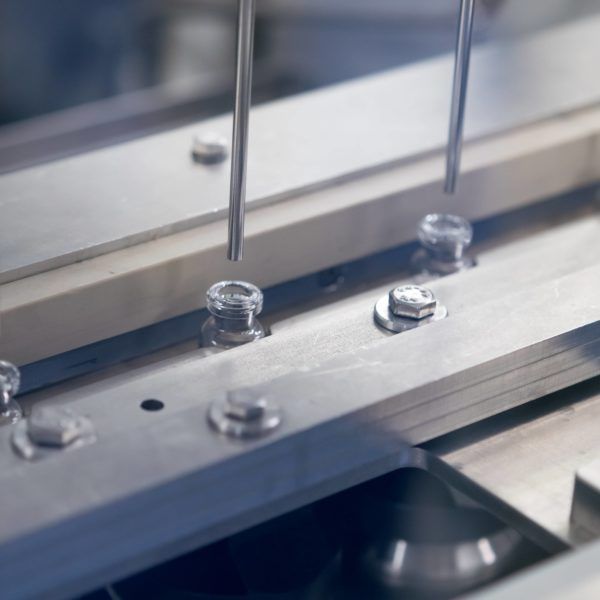

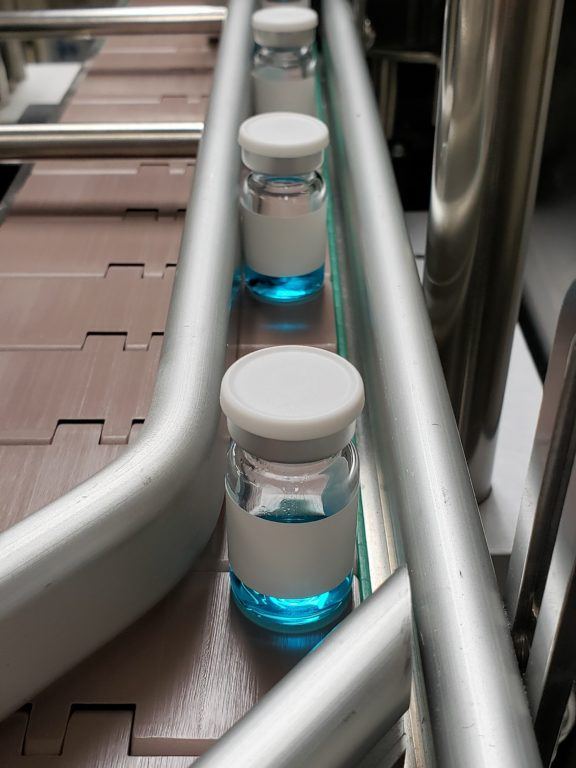

Aseptic Vial Filling

Our aseptic vial filling services take place at four of our five cGMP clinical and commercial manufacturing facilities. We offer both liquid and lyophilized presentations for non-cytotoxic biologics and small molecule parenterals.

Aseptic Vial Filling and Fill-Finish Services

With five aseptic automated fill-finish lines to meet your demands, we have the flexibility to sterile fill a range of batch sizes from a few hundred units to 200,000 units. Starting in Q3 2021, LSNE will be expanding its capacity for Phase I and II clinical programs with the addition of a new fill line and lyophilizer. Ideal for batches 5,000 units or less this new ready-to-use aseptic fill line will utilize fully disposable formulation and manufacturing materials and manage in-line weight checks to limit valuable product loss.

Our aseptic vial filling experience includes:

- Proteins

- Monoclonal antibodies

- Small molecules

- Peptides

- Oligonucleotides

- Liposomes

- Emulsions

- Suspensions

- Hormones

| LSNE-Bedford | LSNE-Madison | LSNE-León | |

|---|---|---|---|

| Vial Size | 2 – 100 mL | 2 – 50 mL | 2 – 30R |

| Fill Volume | 0.5 – 100 mL | 0.5 – 50 mL | 1 – 30 mL |

| Batch Size | Up to 25,000 units | Up to 30,000 units | Up to 200,000 units |

| Lyophilization Capacity | 30 – 270 sq ft | 54 – 144 sq ft | 150 sq ft |

Maximized Yield

No matter your batch size or presentation, we will minimize process loss and maximize overall yield of your valuable drug product. Our cGMP fill finish processes are designed to reduce shear stress as much as possible to prevent aggregation / degradation issues. Extreme care is taken to minimize line loss, which is very attractive to our clients developing very expensive API. Our goal is to help get your product to market and in the hands of patients in need.

Manufacturing Support

Visual Inspection

After your batch is complete, LSNE’s certified technicians will perform 100% manual visual inspection of the finished product.

Labeling and Packaging

LSNE can manage your labeling and packaging needs and perform non-blinded clinical labeling, ink-jetting, packaging and kitting.

Analytical Testing

Take advantage of our in-house GMP analytical testing services to speed turnaround and expedite your timeline.

Controlled Temperature Storage

LSNE offers cGMP validated storage at controlled room temperature, refrigerated and frozen conditions for incoming raw materials and finished product.

Regulatory Support

We have the knowledge and expertise to support your regulatory submissions through every phase of product development.

Our Global Network

Across our network vial filling is the cornerstone of what we do. All our facilities aseptically fill finish and lyophilize drug product in vials.