Syringes

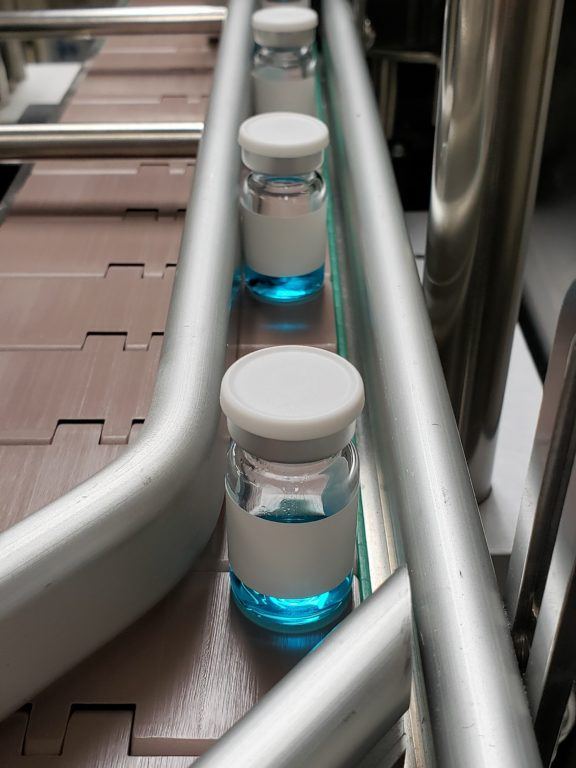

Our aseptic pre-filled syringe filling capabilities include filling solutions, emulsions, and suspensions for small molecules, steroids, and hormones. We’ve invested in specialized equipment to support microfluidization and high shear homogenization for complex formulations such as highly viscous, liposomal and nanoparticles.

Aseptic Syringe Filling

- Syringe sizes – 1 mL, 1 mL long, 2.25 mL and 3 mL PFS

- Fill volumes 0.1 mL to 3 mL

- Batch sizes up to 60,000 units

- Ready to use in nests

- Rotary piston filling technology

- Liquid presentation

- Terminal sterilization

Manufacturing Support

Visual Inspection

After your batch is complete, LSNE’s certified technicians will perform 100% manual visual inspection of the finished product.

Labeling and Packaging

LSNE can manage your labeling and packaging needs and perform non-blinded clinical labeling, ink-jetting, packaging and kitting.

Analytical Testing

Take advantage of our in-house GMP analytical testing services to speed turnaround and expedite your timelines.

Terminal Sterilization

We have the capability to terminally sterilize your pre-filled syringes.

Controlled Temperature Storage

LSNE offers cGMP validated storage at controlled room temperature, refrigerated and frozen conditions for incoming raw materials and finished product.

Regulatory Support

We have the knowledge and expertise to support your regulatory submissions through every phase of product development.

Our Global Network

Talk with us about how we can support your next sterile filling project of a complex formulation in syringes.